Environmental

Water

Initiatives to effectively utilize water resources

The HOYA Group endeavors to effectively utilize water resources in accordance with its Fundamental Environmental Policies. We aim to achieve sustainable water resource management by promoting water reuse and reducing water usage on a global scale.

Water usage reduction targets

We have been setting water usage reduction targets for each business division, taking into consideration the water consumption status of each business division. In order to further accelerate these efforts, the HOYA Group set new water targets for the Group in fiscal 2023.

In particular, we are promoting water use reduction at production sites with high water intake or elevated water stress risk by setting site-specific targets, developing roadmaps, and implementing measures such as process optimization and improved water reuse.

In particular, we are promoting water use reduction at production sites with high water intake or elevated water stress risk by setting site-specific targets, developing roadmaps, and implementing measures such as process optimization and improved water reuse.

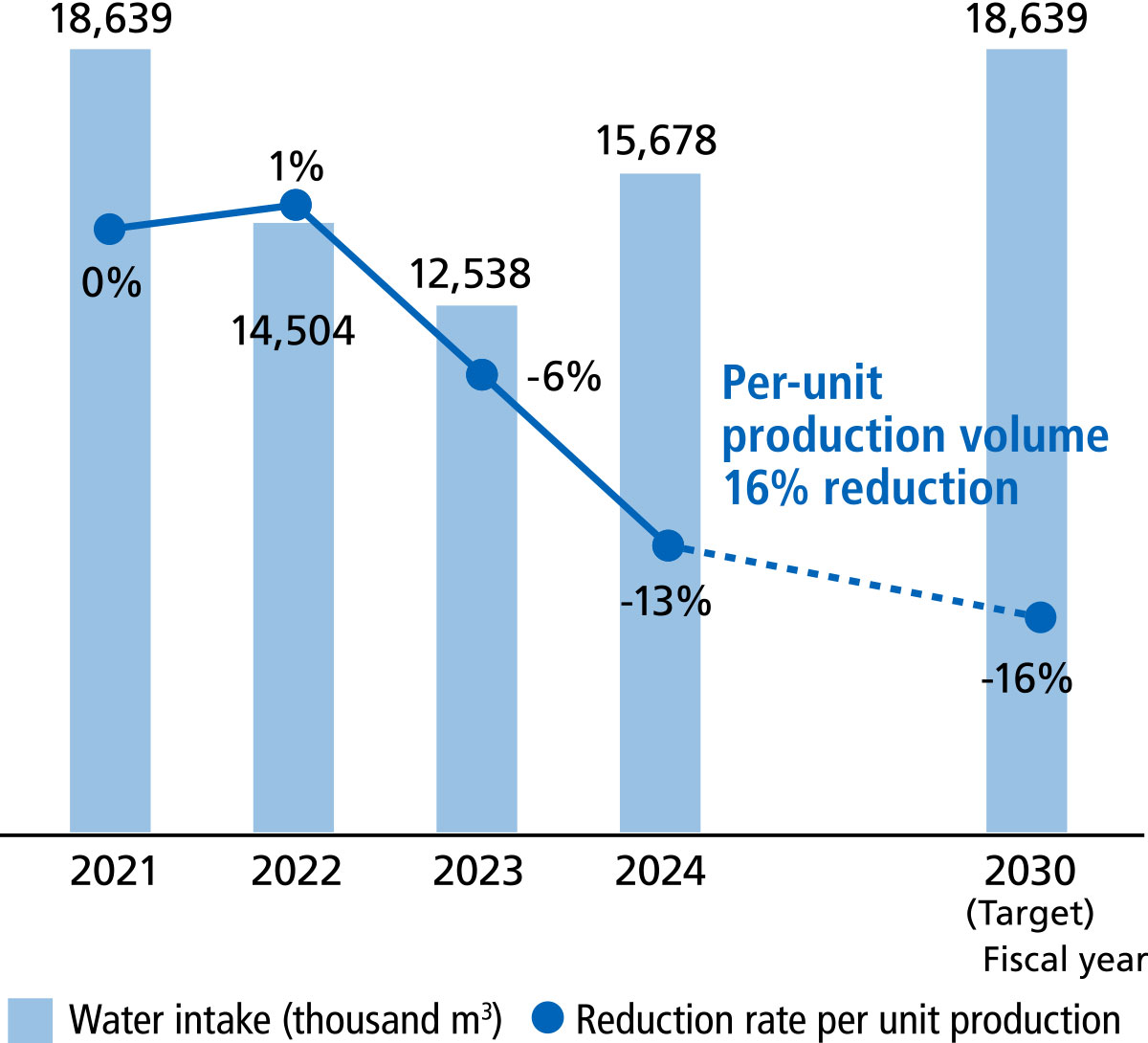

As a result, although production volumes increased in each business division in fiscal 2024, total water use decreased by approximately 16% compared to the base year of fiscal 2021. Furthermore, in terms of water reduction per production volume, we achieved a 13% reduction compared to the previous year.

HOYA Group water consumption (water intake volume) per-unit target:

16% reduction in water intake per number of products produced* by fiscal 2030 (versus the base year of fiscal 2021). However, we will endeavor to keep total water intake volume below the base year level.

* Number of products produced based on an internally established conversion method to combine operations manufacturing different products

Water stress risk assessment

Water is one of the important resources in the production activities of the HOYA Group, and in particular, the MD Division (HDD glass substrates) and VC Division (eyeglass lenses) use large amounts of water in their production processes.

To promote the sustainable use of water resources, we are comprehensively assessing water stress risk for each production site using the Aqueduct Water Risk Atlas, while also conducting interviews at the sites. Those sites identified as high risk collaborate with the Environment, Health and Safety Department at the head office to formulate countermeasures and focus on implementing these measures. Through these initiatives, we aim to achieve both efficient use of water resources and consideration for the local environment.

Water intake

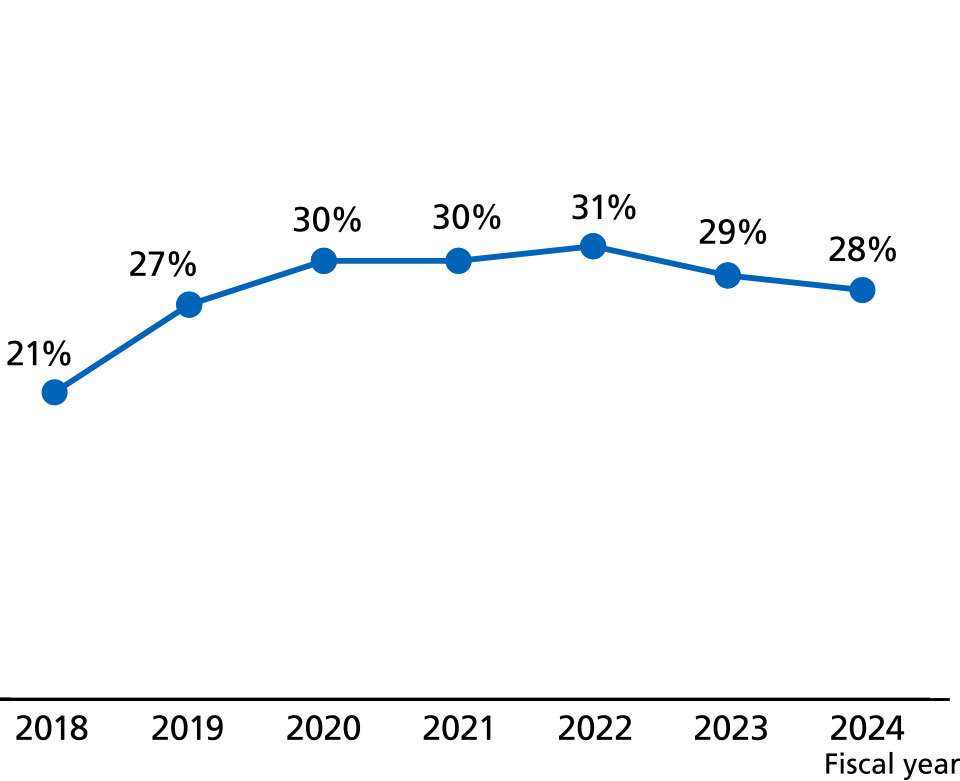

In fiscal 2024, the HOYA Group's water intake totaled 15,678 thousand ㎥, representing a reduction of approximately 16% compared to the base year (fiscal 2021). In addition, water consumption per unit of production was reduced by 13%, and the water reuse rate remained consistent with typical levels at 28%.

On the other hand, compared to the previous fiscal year, water intake and intake per consolidated net sales increased by 25% and 10%, respectively, due to an increase in production volume. However, water intake is being managed at a level below the base year (fiscal 2021), and water intake per unit of production is on a downtrend. This indicates that we are steadily promoting the efficient use of water resources.

Water intake

Water reuse ratio

Water intake volume is calculated based on the amount of municipal water, industrial water, and groundwater used at production sites.

For water-related data, please refer to the Environment page of the ESG Databook.

Initiatives to reuse water

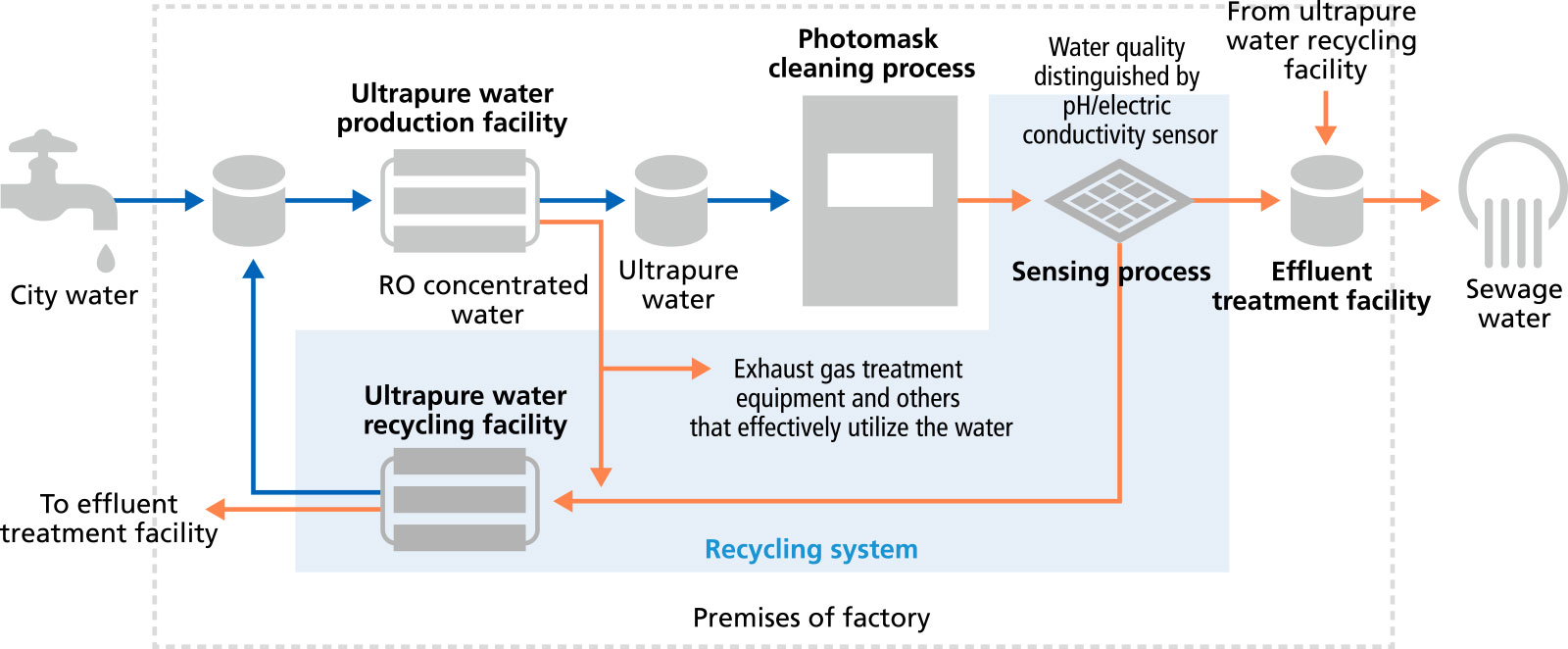

Recycling of ultrapure water in photomask manufacturing process

In the photomask manufacturing process, cleaning is performed by using ultrapure water to remove various chemicals and foreign matter. The used water undergoes a process at an effluent treatment facility to be rendered harmless, some of which is subsequently collected and reused. The ultrapure water recycling facility, which consists of adsorbents and reverse osmosis (RO) membranes, makes it possible to reuse water by removing impurities.

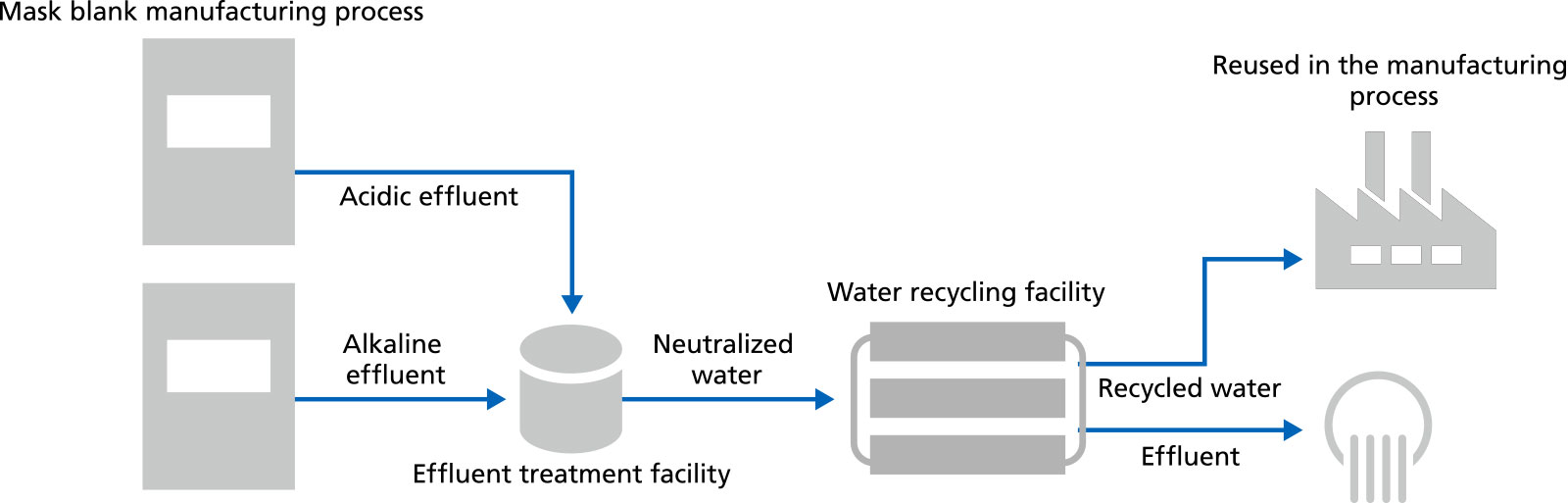

Reduction of chemical substances and water recycling in mask blank effluent treatment

In the mask blank manufacturing process, water and chemicals are mainly used in the cleaning and polishing processes, which then undergo chemical treatment before being neutralized in an effluent treatment facility. EUV (extreme ultraviolet) mask blanks generate acidic effluent, while optical (deep ultraviolet) mask blanks generate alkaline effluent. By mixing these two types of effluent and neutralizing them, we have reduced the use of additional chemicals in effluent treatment. Furthermore, we have succeeded in reducing the amount of water intake by recycling a portion of the neutralized water. This initiative enables us to reduce environmental impact while effectively utilizing resources.