Environmental

Pollution Control Measures and Waste, etc.

Facilities standards and pollution control measures for environmental conservation

In order to prevent harmful effects on the environment inside and outside our business sites, we have established basic specifications for environmental equipment at our business sites in Japan and overseas in the HOYA Group Standard for Environmental Facilities and have established a system to respond to environmental risks such as soil and groundwater contamination and the leakage of hazardous substances.

Specifically, structural safety is secured for tanks, pipes, effluent facilities, etc., and measures are in place to quickly shut off and contain any harmful substances in the event of a leak. To prevent contamination of groundwater, we have adopted a permeation prevention structure for effluent treatment facilities and storage facilities, and have established a regular inspection system.

Furthermore, to prevent the environmental impact of harmful substances from dispersing, leaking, or infiltrating we have established clear emergency response procedures and a system for promptly notifying relevant parties and government agencies. These measures are documented in an emergency response manual, which requires investigation of the root causes and implementation of corrective actions to prevent recurrence in the event of an accident.

Initiatives for chemical substance management

We manage all chemicals used in our business activities across the entire Group in accordance with the HOYA Group Chemical Substances Management Standard, with the aim of preventing accidents, disasters, health hazards, and environmental pollution caused by harmful chemicals. This approach enables us to prevent occupational accidents, such as health hazards arising from chemical substances, while also working to reduce environmental impact. We have established a framework for regularly monitoring and reporting the generation of environmentally hazardous substances, and through risk assessments of the substances we use, we take measures such as appropriate management of chemical substances and consideration of alternatives to further mitigate risks.

Waste management

We have been promoting appropriate waste management and recycling, mainly at our manufacturing sites in Japan and overseas. These activities are positioned as important measures for reducing environmental impact and realizing a circular economy. To further accelerate these initiatives, we have set a new Group target of “80% or more recycling rate for waste” from fiscal 2024. This target will be achieved through improving the accuracy of waste separation at each manufacturing site, expanding processing routes that enable recycling, and strengthening cooperation with suppliers and waste disposal service providers.

In addition, we strictly manage hazardous waste and plastic waste from an environmental risk perspective, collecting and analyzing data on emissions and treatment methods at each site. This enables us to ensure full compliance with laws and regulations and to formulate more effective reduction and reuse measures. In particular, each business is working to strengthen initiatives related to plastics by selecting recyclable materials and exploring alternatives, with a dual focus on reducing waste generation and promoting circular use.

In fiscal 2024, our waste recycling rate was 79.8%, falling slightly short of the target mentioned above. However, we will continue to promote recycling activities in each business division to achieve the target in the future.

For waste-related data, please refer to the Environment page of the ESG Databook.

Initiatives toward a circular economy

HOYA has positioned the promotion of a circular economy as one of its most critical corporate challenges to realize a sustainable society. We aim to simultaneously reduce environmental impact and generate economic value by using resources efficiently and minimizing waste.

Examples of waste reduction and reuse initiatives

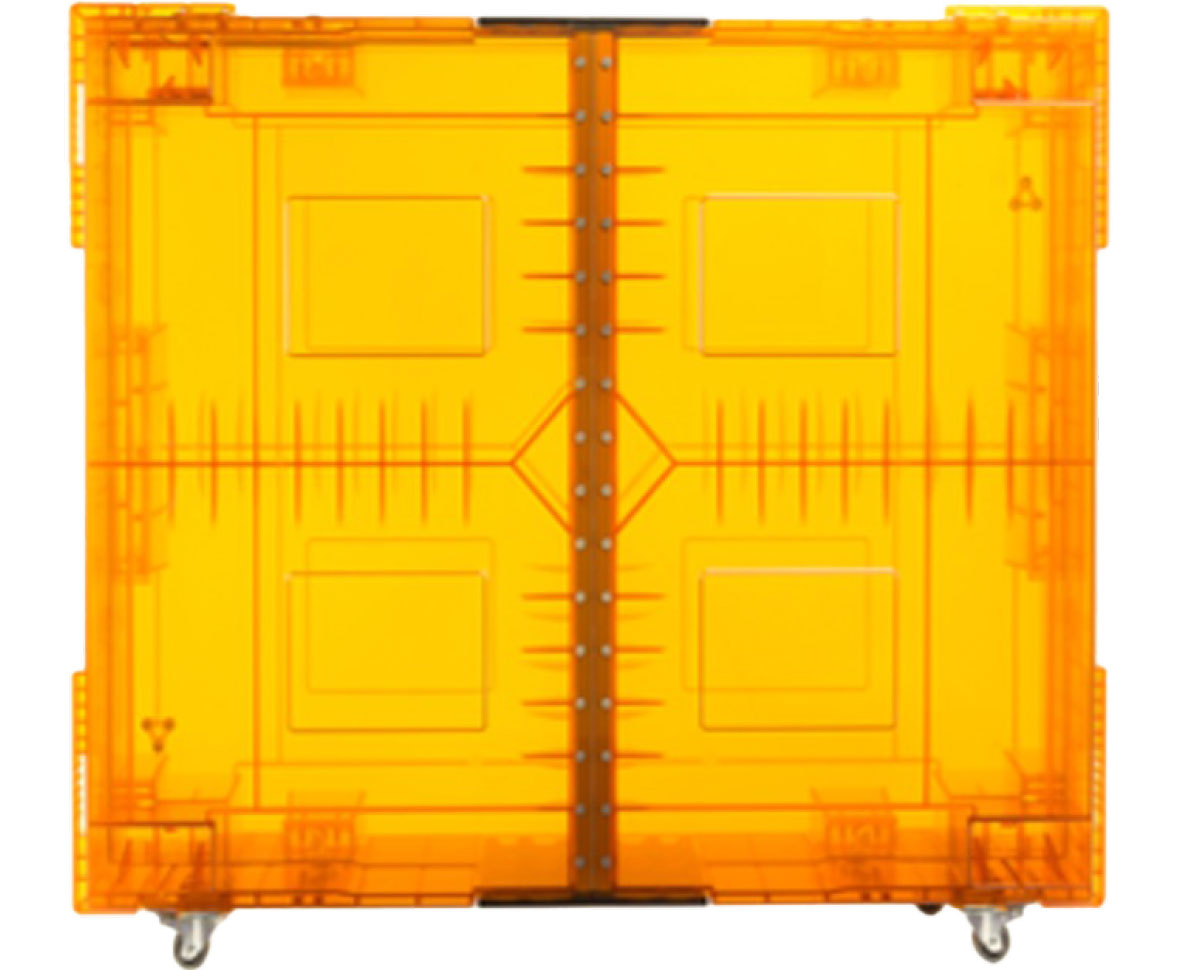

Recycling of photomask transport cases

Photomasks are extremely precise and delicate products, and their transportation requires high quality control. We have developed a process that enables the reuse of plastic transport cases, which were previously used only once before disposal. This initiative has been made possible through collaboration with customers and related suppliers and has been introduced in some photomask sizes and countries. This process has led to a reduction in plastic waste and a reduction in the consumption of virgin resources.

G6-size photomask case

850mm x 1200mm x 10mm

Reducing environmental impact by reviewing packaging materials

Each division is working to reduce waste and CO₂ emissions by reviewing product packaging. We are promoting the optimization of materials used while ensuring product protection and quality during transport.

Examples of initiatives

・We are promoting the switch to paper materials to reduce the amount of plastic used in eyeglass lens packaging. By making this change while maintaining product quality standards, we are helping our customers reduce waste, improving transportation efficiency, and reducing CO₂ emissions throughout the entire process from transportation to disposal.

・Pentax Medical has switched from using 100% polyethylene bags for packaging medical endoscope accessories (treatment supplies) to bags containing 30% biomass material, thereby reducing the use of plastic resources.

We will continue to review our packaging materials to achieve both effective use of resources and reduced environmental impact, while actively pursuing the adoption of eco-friendly materials and technologies in the future.