Response to Climate Change

In 2021, the HOYA Group identified four material issues. Among these, the entire the Group is tackling “reduction of greenhouse gases” as a top-priority issue. In December 2021, the Group endorsed the Task Force on Climate-related Financial Disclosures (TCFD). Pursuant to this announcement, in April 2023, the Group began disclosing information based on the TCFD Declaration, strengthening its response to risks associated with climate change. In February 2023, the Group joined RE100, an international environmental initiative aimed at achieving 100% sourcing of renewable energy for all energy consumed in business activities. The HOYA Group aims to reach this milestone by fiscal 2040 and is accelerating its efforts toward that end.

Strategy for CO2 Reduction

The HOYA Group has been deploying CO2 emission reduction activities globally, focusing not only on “energy consumption” through energy-saving activities at production sites but also using ” renewable-energy usage rate” – in power consumption in business activities as a KPI to reduce CO2 emissions.

CO2 Reduction Targets

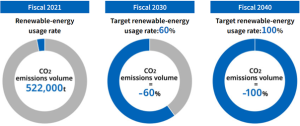

Over 90% of the HOYA Group’s greenhouse-gas emissions (total of Scope 1 and Scope 2) are in Scope 2; the majority of these are indirect emissions arising from purchased electrical power. By aggressively advancing the transition to electricity from renewable sources that do not emit greenhouse gases, the Group is effectively slashing CO2 emissions.

The HOYA Group is targeting complete transition to renewables (renewable-energy usage rate of 100%) by fiscal 2040, with an interim target of 60% renewable-energy usage rate by fiscal 2030.

In line with the group’s goals, each business unit has created a medium- to long-term roadmap for introducing renewable energy and reducing CO2 emissions and has formulated and implemented measures to achieve these goals in the Group-wide effort.

In addition to the upgrading to high-efficiency equipment and energy-saving activities at production sites, we have begun installing solar panels and switching to electricity derived from renewable energy sources both in Japan and overseas.

CO2 emission volume

In addition to previous energy-saving activities, based on each business unit and each country, we are sequentially introducing renewable energy sources that are optimal at the time (switching to renewable energy sources, implementing solar power generation for in-house consumption, etc.). Emissions were reduced compared to the base year and CO2 emissions per unit of net sales were also on a decreasing (improving) trend due to the effects of energy conservation and the introduction of renewable energy, and mainly due to changes in production volume in fiscal 2022.

| K t-CO2e | Unit | FY2019 | FY2020 | FY2021 | FY2022 |

| Scope 1 | K t-CO2 | 21 | 16 | 16 | 13 |

| Scope 2 | K t-CO2 | 398 | 390 | 506 | 486 |

| Total | K t-CO2 | 418 | 406 | 522 | 499 |

| CO2 emissions per unit of net sales | t-CO2 per billion yen |

726 | 741 | 789 | 689 |

| % of renewable energy electricity | % | – | – | 1.4% | 2.2% |

● Scope of data collection: Major overseas production sites, domestic production and non-production sites

● Reference guidelines: GHG Emissions Calculation and Reporting Manual Ver. 4.8 and GHG Protocol

●CO2 emission factors *Including some non-production sites

– Fuel: for outside of Japan – DEFRA Conversion-Factor, for Japan – the list of emissions and calculation methods published by Ministry of the Environment.

– Electricity: for outside of Japan – IEA Emission Factors for each country, for Japan – adjusted conversion factors of the individual electricity supplier contracted by each site based on the Act on Promotion of Global Warming Countermeasures

● To improve the reliability of our calculations, we have undergone third-party verification of our fiscal 2021 GHG emissions (Scope 1 and 2, energy consumption) data at a limited level of assurance.

Energy saving and power saving activities

At production sites, we are replacing facilities with energy-saving types (such as adopting ice thermal storage systems and high-efficiency transformers), conducting energy-saving activities (such as optimizing the operating hours of boilers and air-conditioning equipment) and promoting roof-greening, etc. We are also endeavoring to suppress CO2 emissions from non-production bases by such means as introducing casual wear, adjusting the indoor temperature appropriately and implementing efficient lighting in offices.

Examples of energy/power saving initiatives

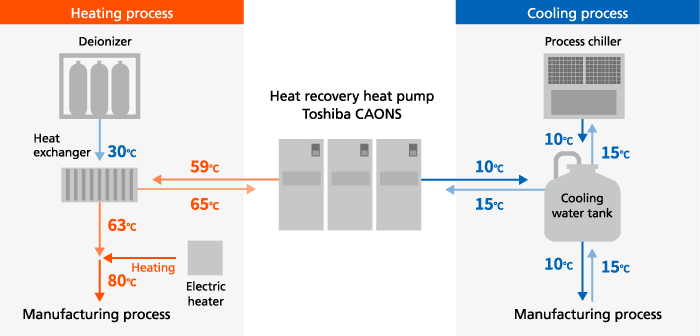

● Use of the Joint Crediting Mechanism (JCM)

● In 2016, we introduced a heat recovery heat pump at the eyeglass lens site in Vietnam. It is used to save energy and reduce CO2 emissions by using the heat that used to be expelled to the outside air when cold heat was supplied as a source of cold heat for the production process and as an auxiliary heat source for heating the water used in the manufacturing process. Before introducing the heat recovery heat pump, we used only electric heaters to obtain the desired temperature.

● At the eyeglass lens site in Vietnam, one of the existing centrifugal chillers was replaced with a highly efficient inverter centrifugal chiller. By using the new chiller for regular operation and the old one as backup equipment, we achieved a lower introduction cost, improved energy efficiency, and reduced CO2 emissions at the same time.

Solar panels installed at HOYA Optical Technology (Weihai) Co., Ltd., Annual power generation: about 1,300 MWh Annual CO2 reduction volume: about 800 t-CO2

● Introduction of Renewable Energy

The HOYA Group is moving forward with switching to renewable energy at each production and sales site. Since fiscal 2022, at HOYA CORPORATION’s Vision Care Matsushima Plant and at HOYA Lens Deutschland GmbH have been running 100% renewable-energy sourcing. In addition, the global head office in Japan has already achieved 100% renewable-energy usage, by means of a feed-in-tariff (FIT) non-fossil-fuel certificate from FIT. Throughout the Group will continue to promote the introduction of renewable energy.

● Installation of self-consumption solar power generation equipment

In fiscal 2022 the Group introduced the first solar-power generation facility on its own premises, building the facility at HOYA Optical Technology (Weihai) Co., Ltd., a production site for optical glass and lenses in Shandong Province, China.